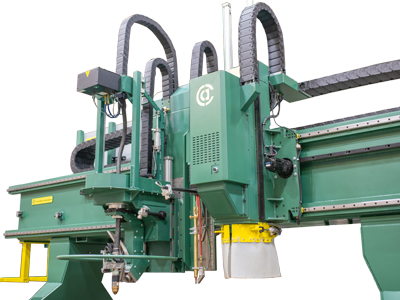

The PlasMAX uses Controlled Automation’s shape cutting technology to produce top quality thermally cut parts. With a core machine design of strength and stability, fast and responsive controls, along with the advantage of oxy-fuel and high definition plasma, precision parts are created quickly and easily. The PlasMAX has many options to fit your specific needs. This machine can be customized to fit your exact requirements, with positioning features such as variable travel lengths, widths, service track positions and material handling options.

The aluminum tubular bridge is driven along the rail system length by use of a AC Servo motor coupled to low backlash planetary gear reducer. We use the highest quality gear reducers on the market to reduce backlash when changing directions and to ensure a very long dependable lifespan. The planetary system produces extreme power and performance in a very small package. 16 pitch gear rack and pinions are used producing optimum plasma and oxy-fuel accuracy and cut quality.

- Laser-Measuring of the plate for higher speeds and accuracy

- Contour Bevel capable

- Ultra-fast speeds of 1,400 IPM

- Water or down-draft cutting surfaces

- Hypertherm True Hole capable with XPR and HPRxd plasma systems

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Machine Specifications | |

| Maximum processing width | 6’ or 8’ (1.8m or 2.4m) |

| Maximum processing length | 4’ to 30’ (1.2m to 9.1m) |

| Maximum material thickness | Dependent on Plasma System Chosen |

| Maximum travel speed | 1400 IPM Compound Motion |

| Cutting Surface | Down-Draft or Water-Table with pull-out trays |

• Aluminum Tubular Bridge (available in 6’ (1.8m) or 8’ (2.4m) material width capacities)

• High Performance Dual Side length Axis Drive Package for High Acceleration

• Industrial Grade Reduced Backlash Gear Reducers

• High Speed Rapid Traverse System (1400 IPM Compound Motion)

• Independently controlled AC Servo Drive Assemblies for both Y and Xa and Xb Axis of motion

• Closed Loop Encoder Feedback built into Servo Motors for Optimum Motor Stability and Protection Against Environment

• Remotely located Electrical Distribution Service Panel and all wiring from it to the Machine

• Power-track System for cable and hose routing to the constantly moving carriage

• 16 Pitch Standard Industrial Grade Rack and pinion for width “Y” Axis positioning

• Tool carriage is held rigid by Precision guide rail technology

• Guide rails and drive rack covered using high temperature and spark resistant bellow covers