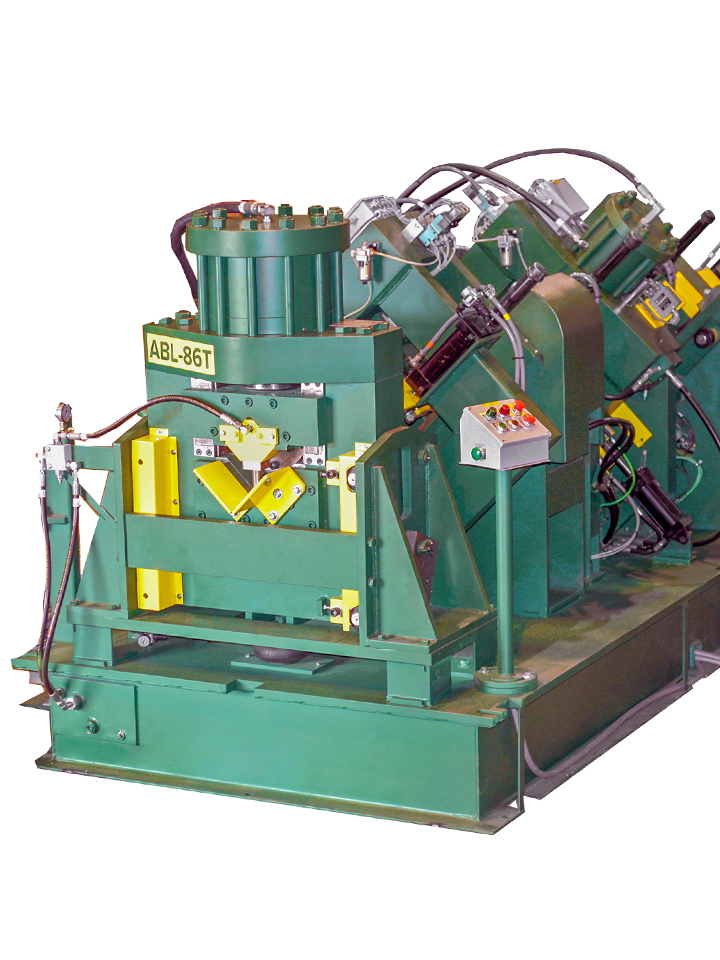

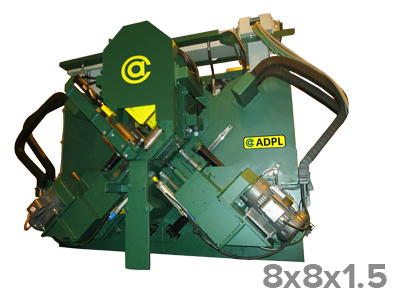

The ABL-86T is a high speed production machine for punching and shearing angle and flat bar up to 6" x 6" x 5/8". As with all Controlled Automation equipment, the ABL-86T is designed to be rugged, reliable, simple to operate and easy to maintain.

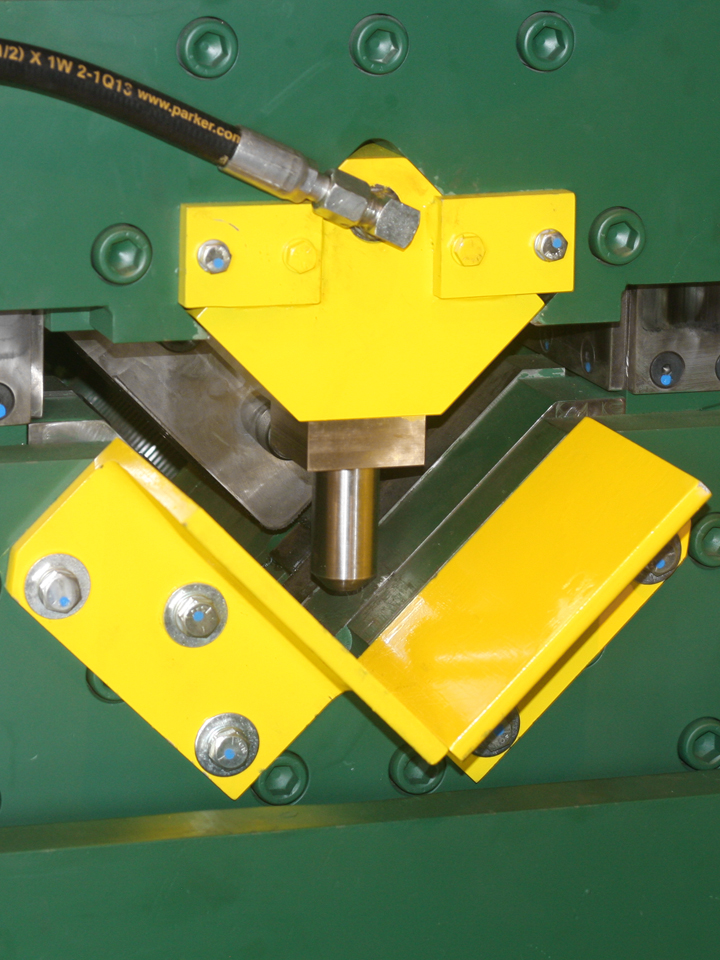

The machine has two 86 ton punch frames, one for each leg of the angle and a few optional features that are not on the smaller ABL-74P. Each punch frame has a single punch standard (Dual-Gag with 2 punches per leg is optional). The punch has extend and retract limit switches to indicate when the punch has extended through the material and when it has fully retracted. The ABL-86T uses continuous material probes so the true material position with respect to the punch is always measured. This achieves greater hole accuracy for both angle and flat bar. Probing is essential on the leading and trailing ends of the material when the material is only clamped on one side of the punch.

- Length Measuring options (Following-Probe, Single-Wheel and Dual-Wheel measuring)

- Dual-Gag option available for 2 hole sizes per leg

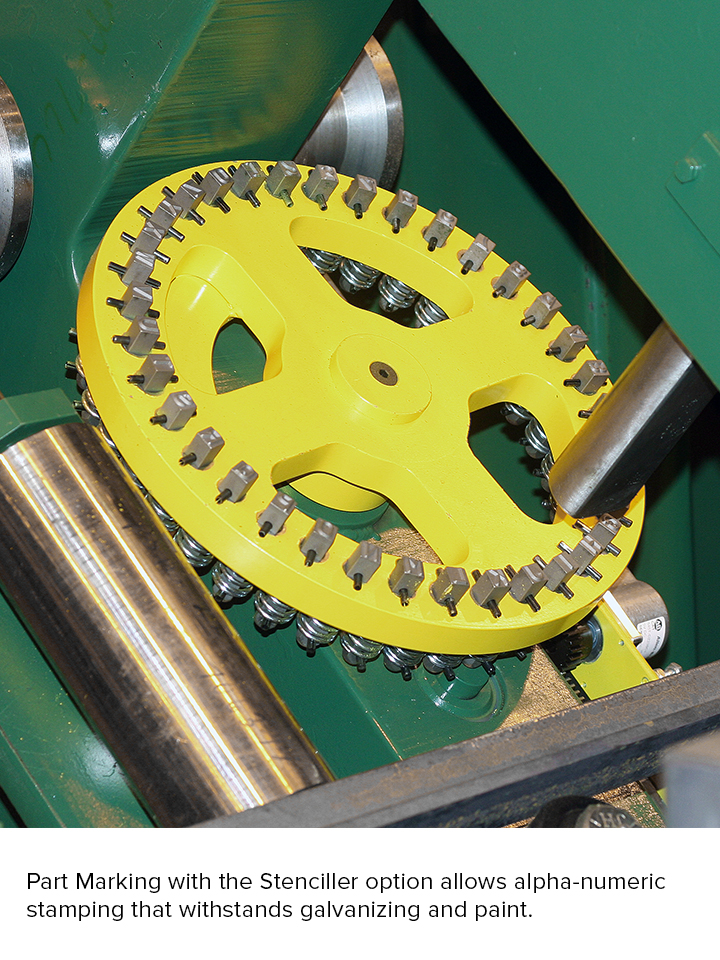

- Part Marking that withstands galvanizing and paint available

- Special angle clearance is optional for 7" x 4" angle clearance

- Loading and unloading features available

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Material Positioning Speed | 0 TO 375 ft/min. (0 to 114.3m/min.) |

| Accuracy | ± 1/32” ( ± 1mm) Electronically |

| Punch Capacity | 86 Tons |

| Maximum Hole Size | 1-1/2” (32mm) |

| Shearing capacity | 250 Tons / Single-Cut |

| Maximum Length of Stock Material | 40’ (12.2m) Standard / other lengths optional |

| Minimum Length of Material | 6’ (1.8m) |

| Maximum Angle Size | 6” x 6” x 5/8” (152mm x 152mm x 16mm) |

| Minimum Angle Size | 1-1/2 x 1-1/2” x 3/16” (38mm x 38mm x 4.75mm) |

| Maximum Flat Bar Size | 5/8” X 6” (16mm x 152mm) |

| Minimum Flat Bar Size | 1/4” x 1-1/2” (6mm x 38mm) |

The ABL-86T is an extremely fast punching and shearing machine for processing angle and flat bar. It has a top positioning speed of 375 ft/min. It can be supplied with three different measuring options of your choice depending on your routine part production. This machine is capable of shearing 6” x 6” x 5/8” angle and 6” x 5/8” flat bar.