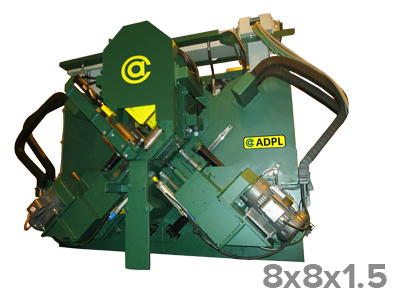

High volume angle production and high accuracy can be achieved on our entry-level ABL-74P angle line. This high speed clip machine offers what few others do at higher prices: ZERO kerf, single-cut shear, punching on both legs and high accuracy Probe Measuring. With our 6" x 6" x 1/2" capacity single-cut shear, you do not have a material loss (slug) for each shear process - saving you money every time you cut. For affordable tooling, the ABL-74P uses inexpensive punches and dies from Cleveland Punch and Die which last longer and process much faster than more expensive drill tooling. Our ABL-74P is made with quality and pride for years of production and years of profit.

- Single punch on each side of angle

- Single-Cut Shear for no loss of material

- Measuring probe that feeds all the way to the shear

- Optional In-Feed loading and Out-Feed conveyor and dump options

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Material Positioning Speed | 0 TO 180 ft/min. (0 TO 54.8m/min.) |

| Accuracy | ± 1/32” ( ± 1mm) Electronically |

| Punch Capacity | 74 Tons |

| Maximum Hole Size | 1-9/16” diameter (39.65mm dia.) |

| Shearing capacity | 6" x 6" x 1/2" (152mm x 152mm x 12.7mm) |

| Maximum Length of Stock Material | 40’ (12.2m) Standard / other lengths optional |

| Minimum Length of Material | 6’ (1.8m) |

| Maximum Angle Size | 6" x 6" x 1/2" (152mm x 152mm x 12.7mm) |

| Minimum Angle Size | 1" x 1" x 1/8" (25mm x 25mm x 3mm) |

| Maximum Flat Bar Size | 6” x 1” (152mm x 12.7mm) |

| Minimum Flat Bar Size | 1" x 1" x 1/8" (25mm x 25mm x 3mm) |

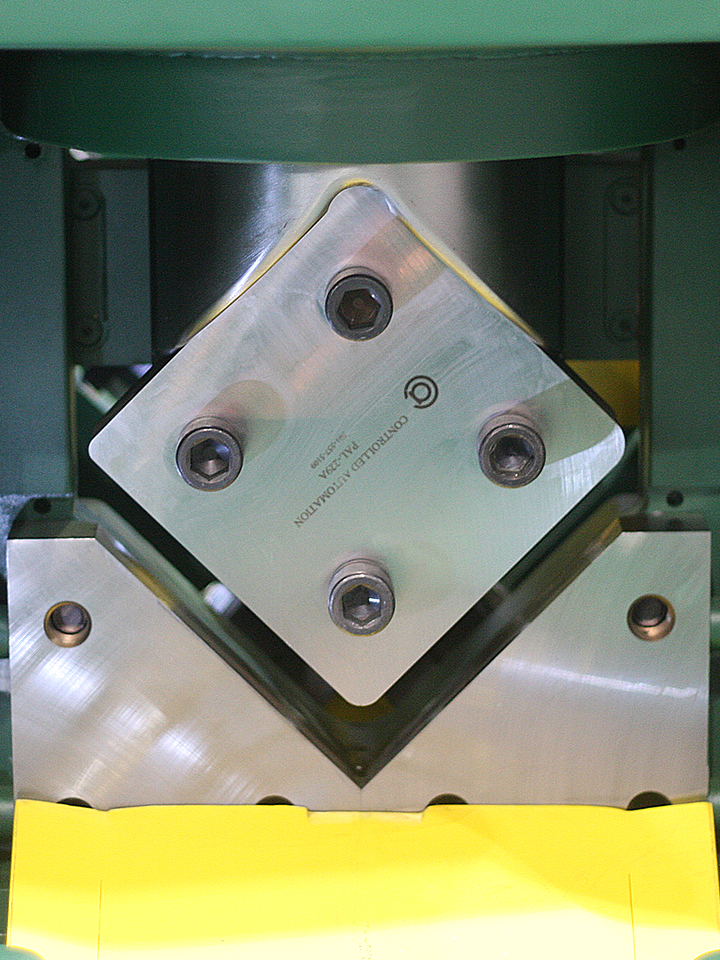

The ABL-74P shear is designed for a long trouble free life, but with more features than competitive units. It has a single cut shear design, which means there is no loss of material when shearing, unlike some competitors' machines. The shear’s extra stiff design provides cleaner cuts with less distortion, and provides longer shear blade life. A separate part chute can direct short parts directly into a cart or bin. To achieve superior cut quality on all angle thicknesses, the reversible and indexable male blade is designed with four different corners to help match the angle with less distortion. The blade may be rotated to accommodate the different material thicknesses and sizes. The blade life is prolonged by using all four sides. It is also designed large enough to allow it to allow sharpening, which leads to an even longer life.

This machine has two 74 ton punch frames, one single punch for each leg of angle. The punch has extend and retract limit switches to indicate when it has extended through the material and when it has fully retracted. These frames are designed for easy access to the punch and die. This provides quicker tooling change times for varying hole sizes. The punch frames are positioned hydraulically using a computer controlled hydraulic valve system. The valve system provides fast, accurate positioning of the punch frames. Each punch frame is unique in automatically positioning material against the die while the punch is retracting. This gives better hole quality and improved punch and die life. The punch units are also extremely rugged in design, which will provide exceptionally long service. The tooling holders are machined for locating keys and pins and for use with non-round punches and dies. The frame positioning wheel assemblies are designed to allow the frames to “float” when punching bent material which reduces stress.

The ABL-74P can also be provided with wheel-measuring and combination tack-weld station for a continous run of material instead of the standard probe measuring. This model, the ABL-74T, is an even more economical model design and ideal for production of clips that do not require high accuracy needed for long span parts (Positioning Accuracy ±.1/16"in.).