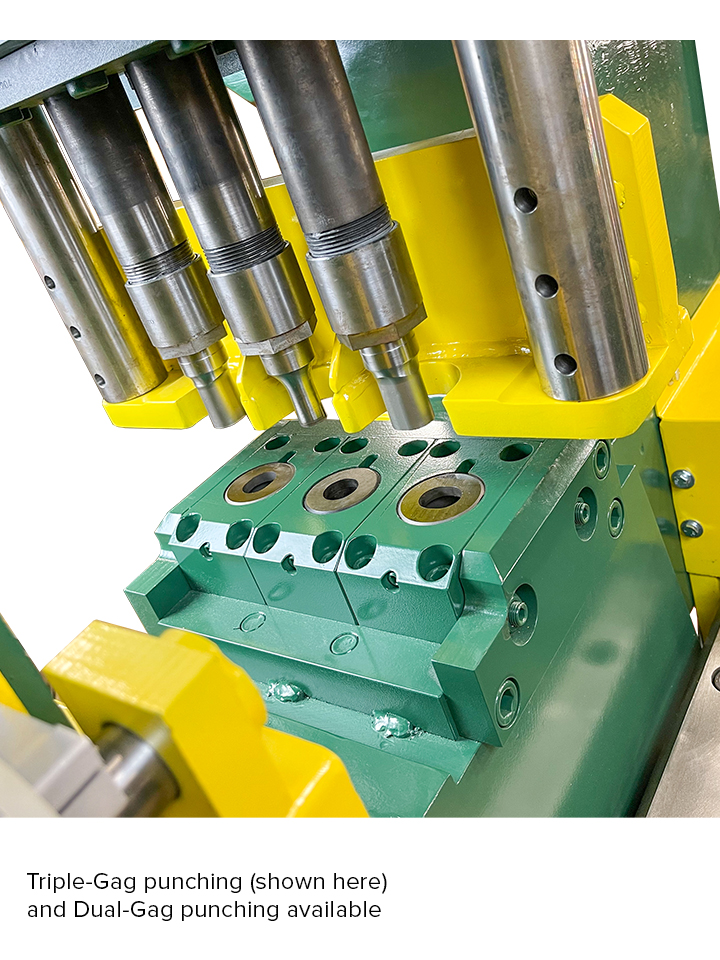

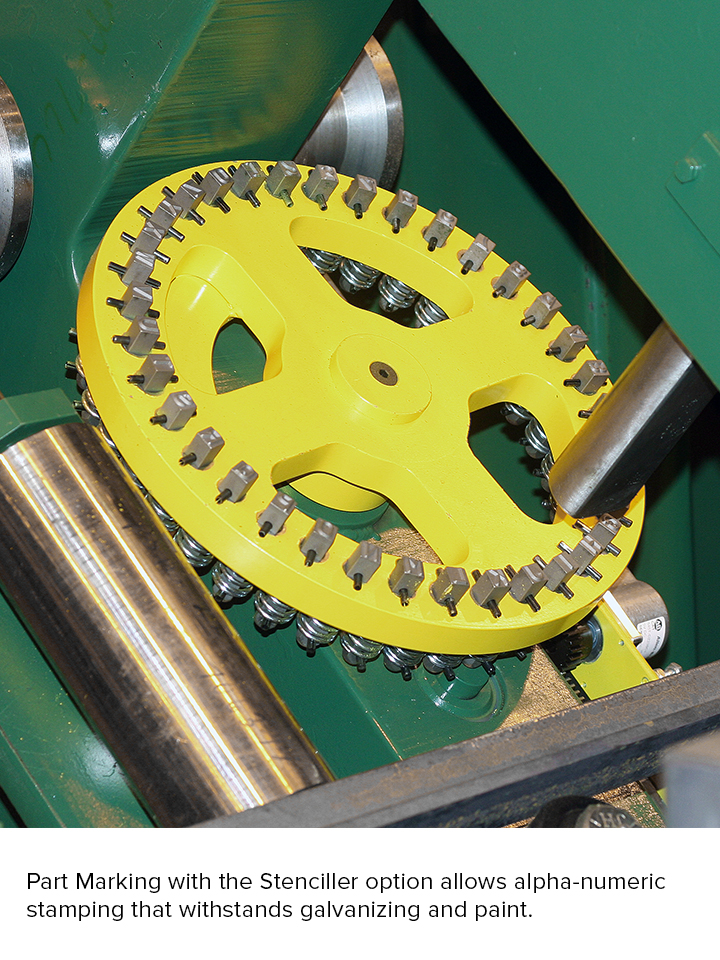

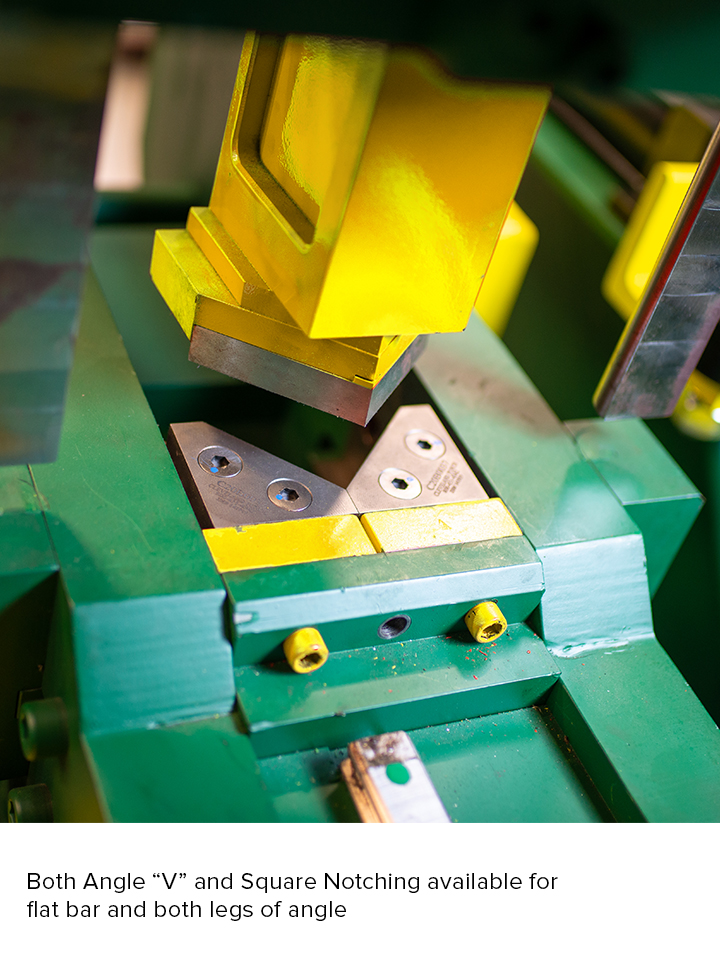

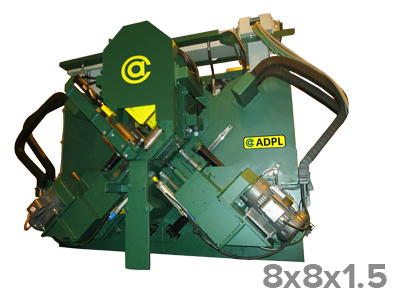

The ABL-100HS is the most versatile, and fastest large angle and flat bar punching and shearing machine on the market today. The high speed servo motor, continuous probing, continuous clamping, and valve positioning software make it not only fast but very accurate. The ABL-100HS is offered by Controlled Automation with such options as, 143 ton single, double or triple-gag punches, single cut shear options ranging from 6"x6"x1/2" up to 8"x8"x1", a variety of length measurement options as well as part marking and stenciling options.

The punch frames are a closed “O” style frame, not an open “C” frame as with most machines. This means that the frames deflect less during punching, which in turn provides a longer tool life. As with all Controlled Automation machinery, the majority of the parts are manufactured in house, including the electrical panels, the guide ways, and clamps.

- Dual-Shear options available

- Angle and Square Notching available

- Part Marking that withstands galvanizing and paint available

- Optional Single, Dual and Triple-gag punches

- Specialized Channel-Shears are also available

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Material Positioning Speed | 0 TO 250 ft/min. (0 TO 76.2m/min.) |

| Accuracy | ± 1/32” ( ± 1mm) Electronically |

| Punch Capacity | 143 Tons |

| Maximum Hole Size | 1-9/16” dia. slug size (39.65mm dia. 12mm thickness) Optional tooling available for larger slug size |

| Shearing capacity | Shearing Capacity depends on shear selected |

| Maximum Length of Stock Material | 40’ (12.2m) Standard / other lengths optional |

| Minimum Length of Material | 6’ (1.8m) |

| Maximum Angle Size | 8” x 8” x 1” (203mm x 203mm x 25mm) |

| Minimum Angle Size | 1-1/2” x 1-1/2” x 3/16” (38mm x 38mm x 4.75mm) |

| Maximum Flat Bar Size | 12” x 1” (304mm x 25mm) |

| Minimum Flat Bar Size | 3/16” x 2-1/4” (5mm x 57mm) |

| Maximum Channel | 10” (254mm) |

| Minimum Channel | 3” (76.2mm) |

With an extremely robust construction, the ABL-100HS is guaranteed to withstand years of rigorous workload normally associated with the structural steel fabrication industry and other industries utilizing angle and flat bar processing.

The punch frames and clamps are mounted onto the surface of a steel platform which is reinforced with steel braces inside. The punch frames are flame cut from solid steel plates, which are machined to suit the design of each particular machine in our own machine shop. Most machine plumbing, both gas and air, along with all electrical wiring is routed through the machine base to eliminate tripping hazards and clutter on and around the machine. This machine base is engineered with the rigidity to support the shearing and punching operations, and to maintain consistent part accuracy over years of strenuous angle and flat bar production.

The ABL-100HS is offered with 143 ton punch frames for single, double and triple gag punches. The punch frames are a closed “O” style frame, not an open “C” frame as with most machines. This means that the frames deflect less when punching at higher tonnages, which in turn provides a longer tool life. As with all Controlled Automation machinery, the majority of the parts are manufactured in house, including the punch and shear frames, guide ways, clamping assemblies, electrical panels and software.

Our ABL-100 has been one of our most most dependable CNC machines here at Capone Iron. A true workhorse that has given us dependable service day in, day out. Any problems were minimal at best and resolved within a short period of time as parts, service and support were always available.

Our ABL-100 has been extremely reliable and near "bulletproof". Purchased in 1997, it has been one of the best investments we ever made.

The ABL-100HS angle machine is a work horse piece of equipment, that I would recommend. It quickly and efficiently makes our standard clip angles. In addition, the stenciling feature works well with where angles and plates require hot dip galvanizing. In short it this piece of equipment is one of the best purchases we have made.

The ABL-100 we purchased from Controlled Automation has been a great machine. It has been a great cost savings for us with labor and material. I would highly recommend this product to any manufacturing company.