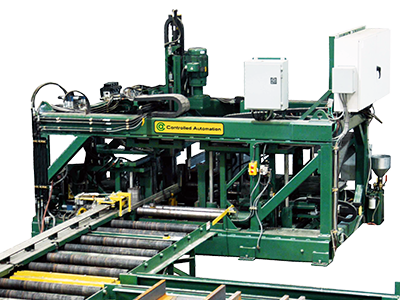

Connection and Base Plate Processing

Controlled Automation’s Detail Production Line is one of our most in demand metal building system machines. This machine is for anyone serious about producing connection plates and base plates up to 1” thick by 12” wide. Controlled Automation continues to serve the metal building industry as the strongest supplier of beam punch lines, anglelines, plate cutting machines as well as our other fabricating machinery, and material handling systems, providing complete plant automation. Any manufacturer equipped with this Detail Line, a Flange Line and web cutting isoMAX plasma cutting table will be able to compete with any metal building company.

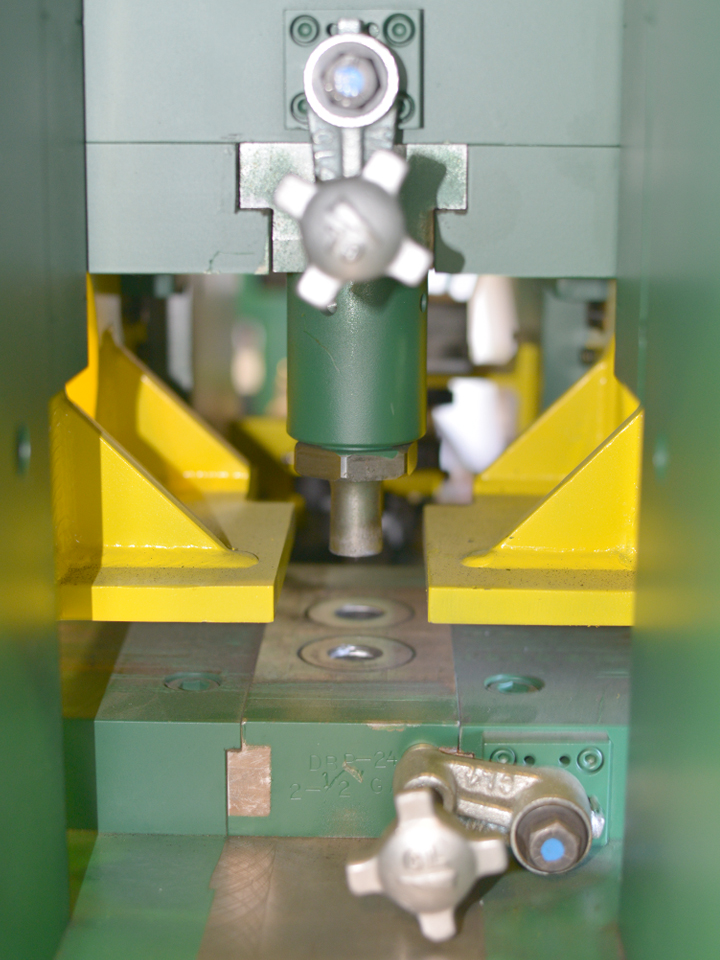

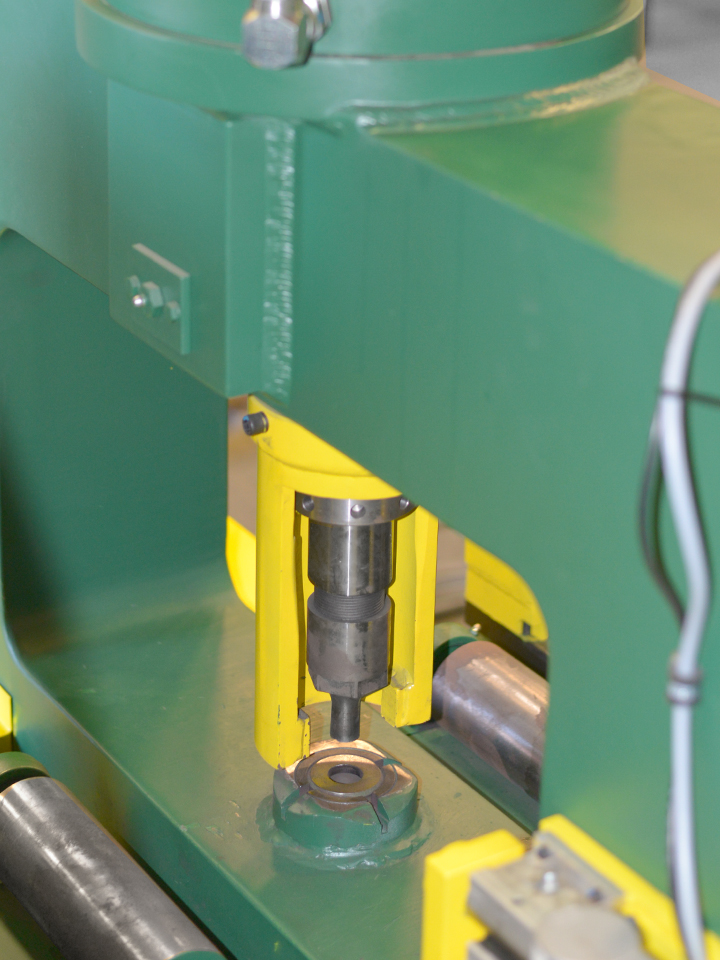

The Detail Line has two punch frames available, and either one or both can be selected. The standard Double Punch frame punches two holes per cylinder stroke, at a selected gage. This is designed to mass-produce connection plates with two holes. The single punch frame punch holes at almost any gage, and multiple gages per part. This frame is perfect for job shops that require versatility and high-tonnage punching.

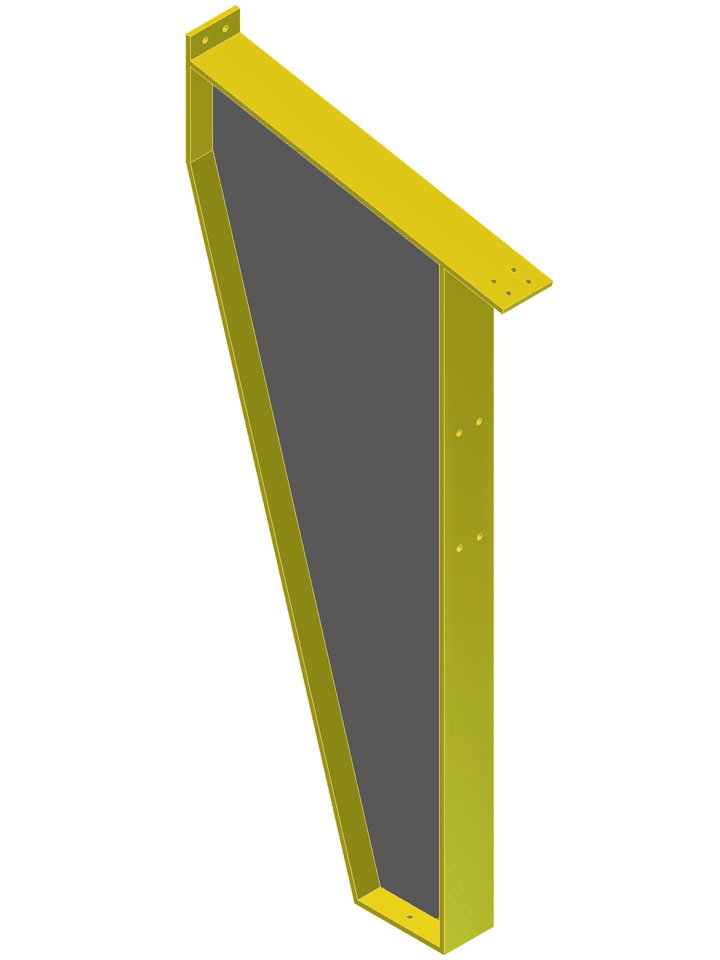

Our single-cut shear has zero kerf (no wasted material). It has an integrated in-feed hold down and out-feed material support cylinders to securely hold the material while shearing. The slight rake angle of the blade, along with the material support cylinder, creates an accurate and clean cut with very square edges every time. It has standard extend and retract limit switches as well as an encoder to allow the shear to retract only enough to clear the material being cut.

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Material Positioning Speed | 0 to 180 ft/min |

| Accuracy | +/- 1/32" |

| Maximum Material Size | 12" (304.8mm) x 1" (25.4mm) |

| Minimum Material Size | 2-1/2" (63.5mm) x 1/4" (6.35mm) |

| Standard 250 Ton Double-Punch | Max Hole: 1-5/16" (33.3mm) through 1" (25.4mm) @ 70 ksi shear strength |

| Standard 215 Ton Single-Punch | Max Hole: 1-11/16" through 1" @ 80 ksi shear strength |

| Kerf | 0 |

The Detail Line control system has an easy to use interface. As the machine runs, the status of each part or operation changes in real time. A part list dialog can be displayed to show which parts have been completed or which operations are remaining. The Windows controller can be easily networked for downloading of parts from the office or by most drafting and design programs. Parts can also be easily programmed at the machine, even while parts are being run.