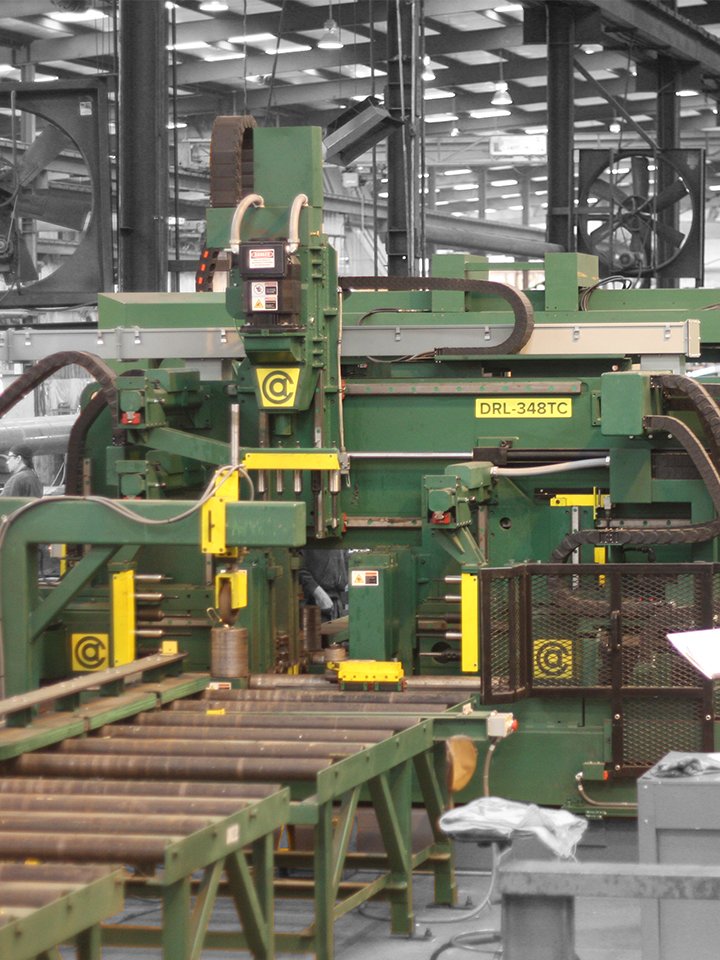

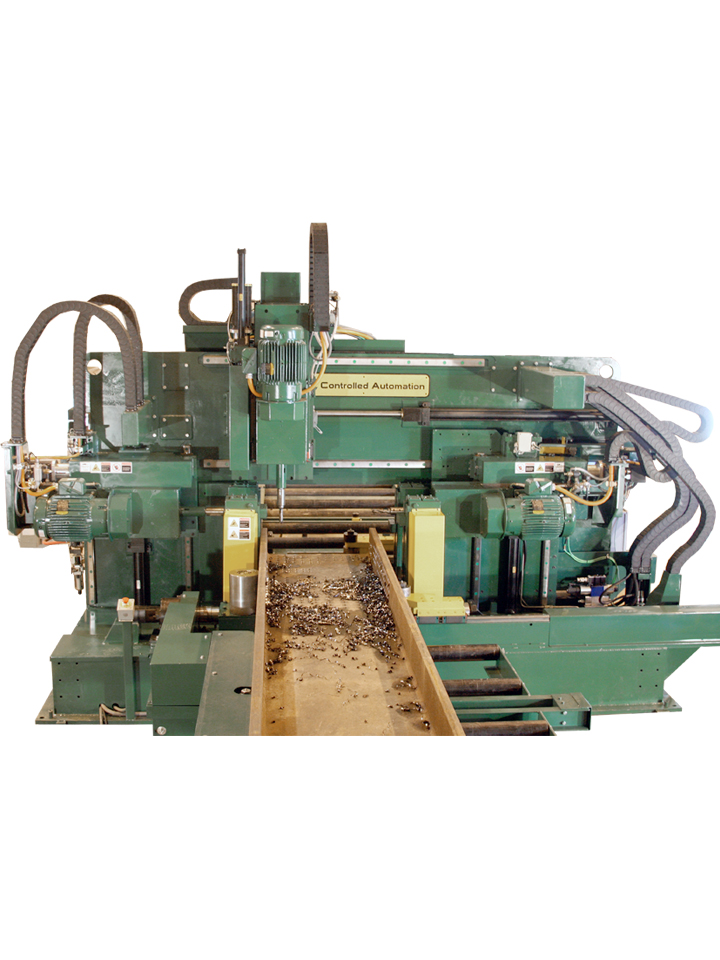

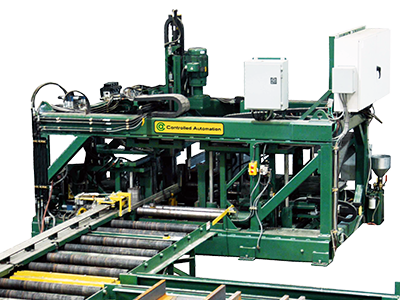

We produce the DRL-348TC 3-spindle drill line without any limitations for the structural steel or bridge fabricator. Each of the 3 spindles operate with a precision ball-screw feed (instead of a hydraulic ram) for fast carbide drilling capabilities. On each axis you have an automatic 5-station tool changer for flexibility of operation on parts with more than one hole size. The build quality on the DRL-348TC is like no other drill - built like a tank with a weight of over 30,000lbs for handling years of rugged use in a harsh environment. Controlled Automation designed it to handle the LARGEST 48" (1.2m) wide 1,000lb per foot (1,488kg/m) material with ease. Our unsurpassed X-probe measuring system ensures you have EXACT measurement on the length of your material far exceeding the accuracy of a wheel measurement tool by any manufacturer.

Our computer control feedback on the spindle drives and ball-screw are monitored to alert the control of worn tools. The worn tools can then be automatically changed to a new replacement and continue the drilling process without any operator intervention.

- Three CAT40 spindles

- Automatic 5-station tool changer per axis

- Material up to 48" wide 1,000lb per foot

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Maximum material lbs/ft | 1000 lbs/ft (1488kg/m) |

| Maximum material height | 18” (457mm) |

| Maximum material width | 48" (1.2m) |

| Maximum Hole Size | 2-1/4" (57mm) |

| Spindle Type | CAT40 |

| Minimum material height | 3/4” (18mm) |

| Minimum material width | 4” (101mm) |

| Minimum material stock length | 9’ (2.7m) |

| Minimum angle size | 4” x 3” x ¼” (101mm x 76mm x 6mm) short leg vertical |

| Material types | W, HP, C, MC, L, HSS (tubing), PL, FB |

More efficiency means more production out the door. The Controlled Automation DRL-348TC comes loaded with 5 automatic tool-changers on each axis to allow for marking and drilling of various size holes without stopping your production. Our computer control feedback on the spindle drives and ball-screw are monitored to alert the control of worn tools. The worn tools can then be automatically changed to a new replacement and continue the drilling process without any operator intervention.

The Controlled Automation control features keep tooling costs at the very minimum while producing the parts quickly and more efficiently than other conventional designs. Our extensive Drill Tool Database provides users with a full list of bit types to choose from in conjunction with the material grade to ensure the most accurate usage and the longest possible life for that particular tool. All records and entries for drill tools are expandable and editable by the user, if so desired, in order to meet a higher demand of performance from the operation or to fine tune any new or existing tool product. The monitoring of worn tools can be automatically changed to a new replacement and continue on with the drilling process using the automatic tool-changer.

There is no comparison between Controlled Automation’s drill line and the competition. We have had other, maybe better known machines and their machine and service doesn’t come close to Controlled Automation. Experiences with the competition in the areas of service, price, tech help and parts have totally sold us on Controlled Automation. Their machines are just all around better. Their software is great. It’s so uniform; once you train someone on one machine they can run any machine. And if I “holler” they come. If I have my way we will never have anything but Controlled Automation machines.

When buying a drill line the first thing that I looked at was price. Controlled Automation has a lower price, but the value hasn’t been compromised. Their service is very, very good… always right here when I need them… always available. Rob Roberts, the engineer who designs the drill line usually calls me back within five minutes if I ever have a question. Another thing that helps is all parts are off the shelf parts from their shop and any smaller parts are available through any catalog or through a local dealer if I want to buy them that way. You cannot get a better machine or better service.

Industrial Steel Construction has been in business for over 35 years. We have two bridge fabrication facilities. 170,000 square foot facility, located in Illinois, is used to fabricate small girder bridges, as well as rolled section bridges. The second plant, a large 1.6 million square foot facility, located in Northwest Indiana, is dedicated to large plate girder type bridges, and was formerly the American Bridge Company. We have shipped the largest girders ever shipped in the Midwest; six girders for Metra that were 17’ deep by 160’ long and weighed 140 tons per girder, form this Indiana plant. At our Hodgkins operation, we are fabricating a 25,000 ton rolled section structure for the CTA, that is 6 ½ miles long, and has well over a million drilled holes of various sizes. This project contributed to the need for an automated drill line. After extensive research we purchased the Controlled Automation drill line, in conjunction with the HE&M Saw model WF-190, and after six months of operation we find them performing beyond our expectations. Before awarding the contract to Controlled Automation, we looked at all the other equipment available on the market, including Peddinghaus. Peddinghaus was the obvious source for equipment, as they are located less than 50 miles from our Hodgkins facility, and have a sound reputation. After several failed attempts at a demonstration of the Peddinghaus drill line, our frustration led us to Controlled Automation. During our visit to the Controlled Automation plant in Arkansas, they delivered a flawless demonstration of their drill line. Controlled Automation furnished a customer list, from which I randomly selected a few, because they were geographically far apart, to contact regarding their experience with the equipment. They were: La Jeune Steel, AFCO / W&W Steel, and Southern Bleacher. They gave me the highest recommendations I have ever heard on any company. Because of the demonstration, and the glowing recommendations from their customers, we purchased the equipment from Controlled Automation. The installation and startup went smoothly, and their service is incredible. The accuracy of the equipment, which is stated conservatively in their literature, is beyond what I had anticipated. The drill is also very low maintenance. We are now looking at purchasing several more pieces of equipment, including the Angle Line, and a burning machine, based on the quality of the drill line.