Flange Production for

Pre-Engineered Building Systems

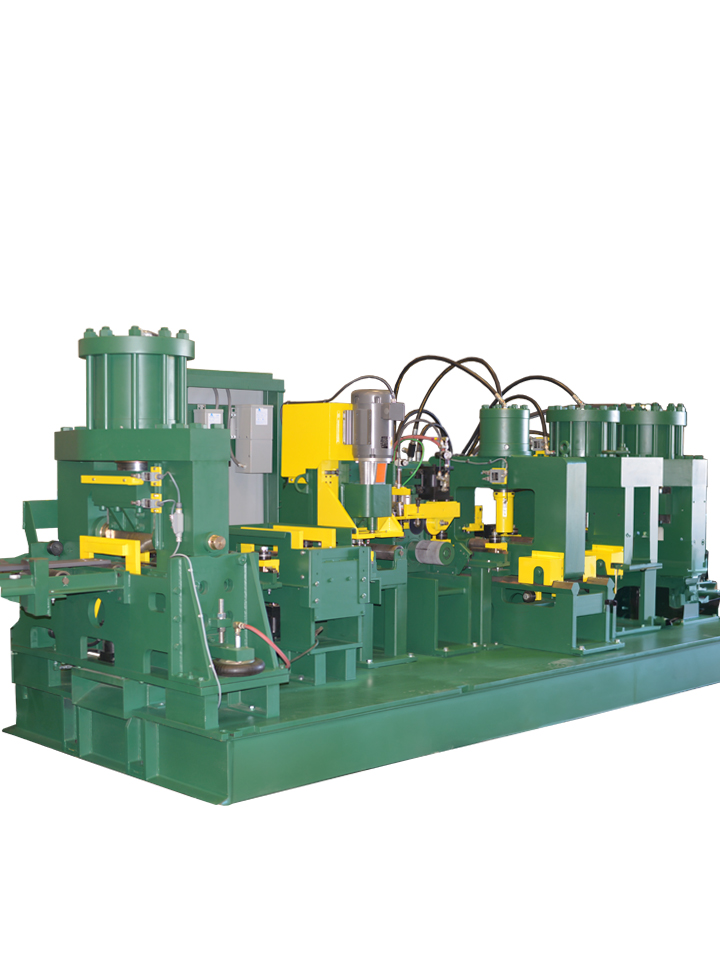

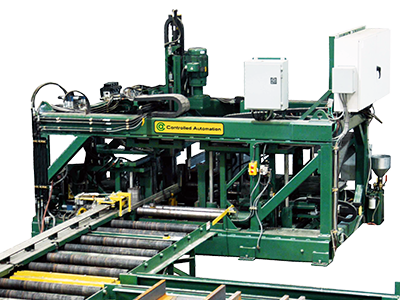

These machines are to produce flanges for welded beams. The material is butt welded end to end to allow for continuous processing of the material. The function of the machine is to process flat bar or plate from 4” to 12” in width and 3/16” to 1” in thickness. The machine will have a 40’ long out-feed that will discharge the material to one side of the out-feed conveyor. Optional longer out-feeds are available. The standard machine consists of a 40’ long powered in-feed conveyor (standard), squaring shear (for accurate weld alignment), one single punch station (optional), one double punch station (optional), a weld milling cutter, sub-arc auto welding station (optional), hydraulic power unit and a single-cut “cut to length” shear. All components are mounted on a steel base, complete with servo material positioning wheel, material lift rollers and centering clamps. Material handling systems are also available for loading material on to the in-feed.

Features:

- Squaring Shear for accurate welding alignment

- Sub-arc welding station for continuous material

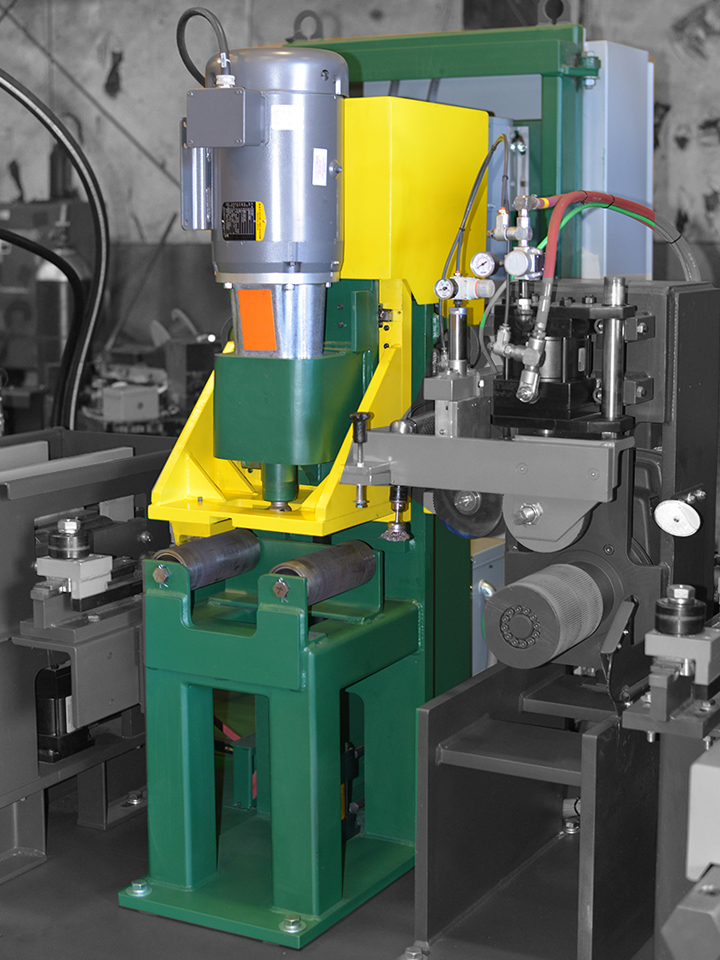

- Milling station to remove weld

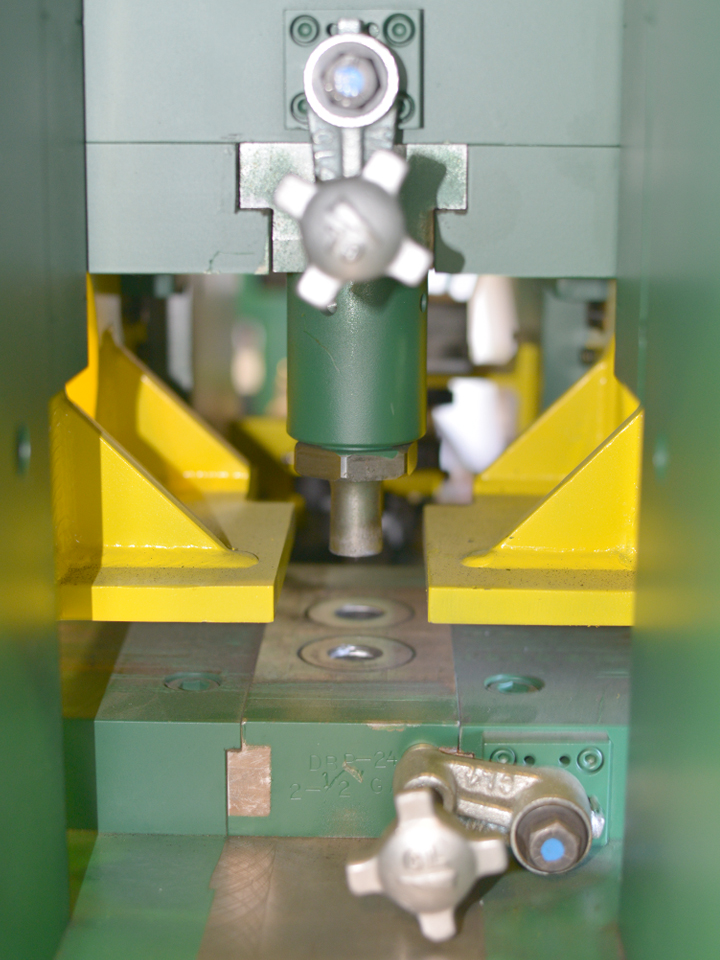

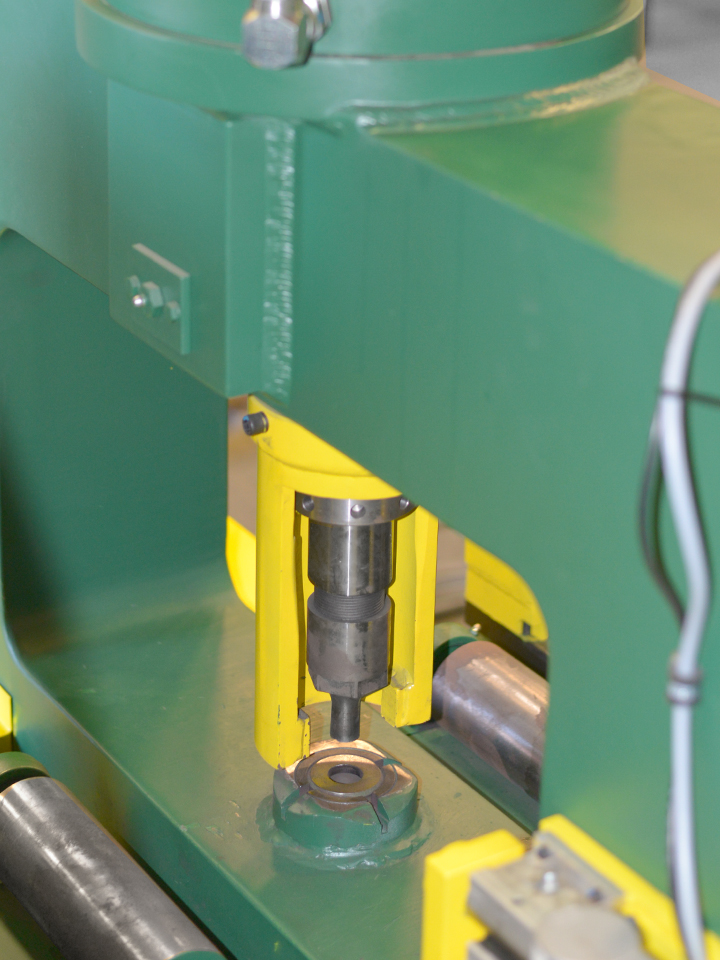

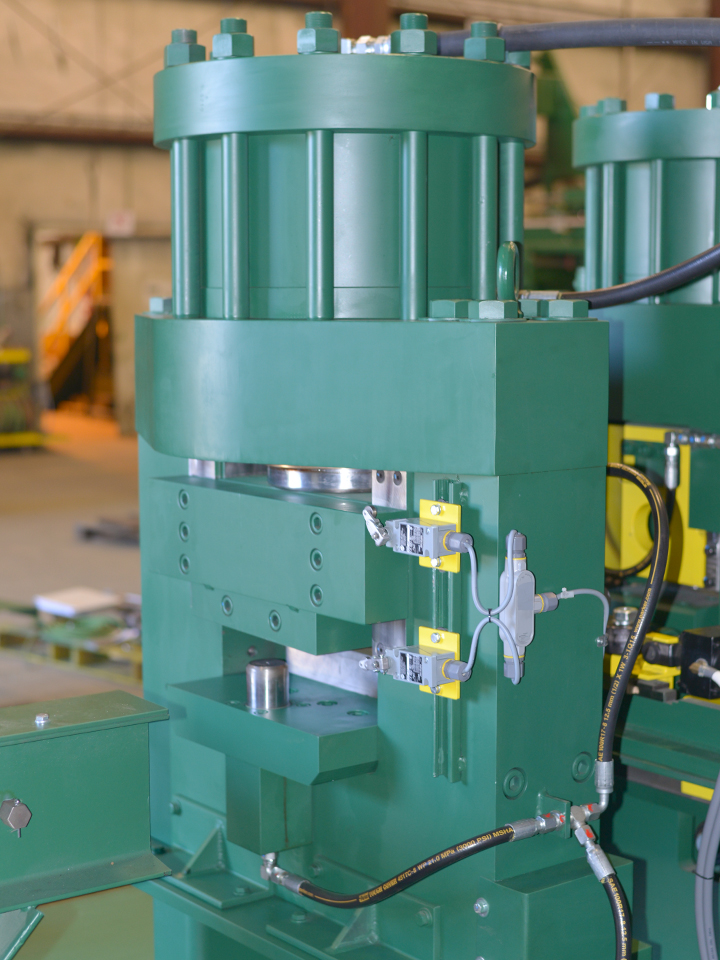

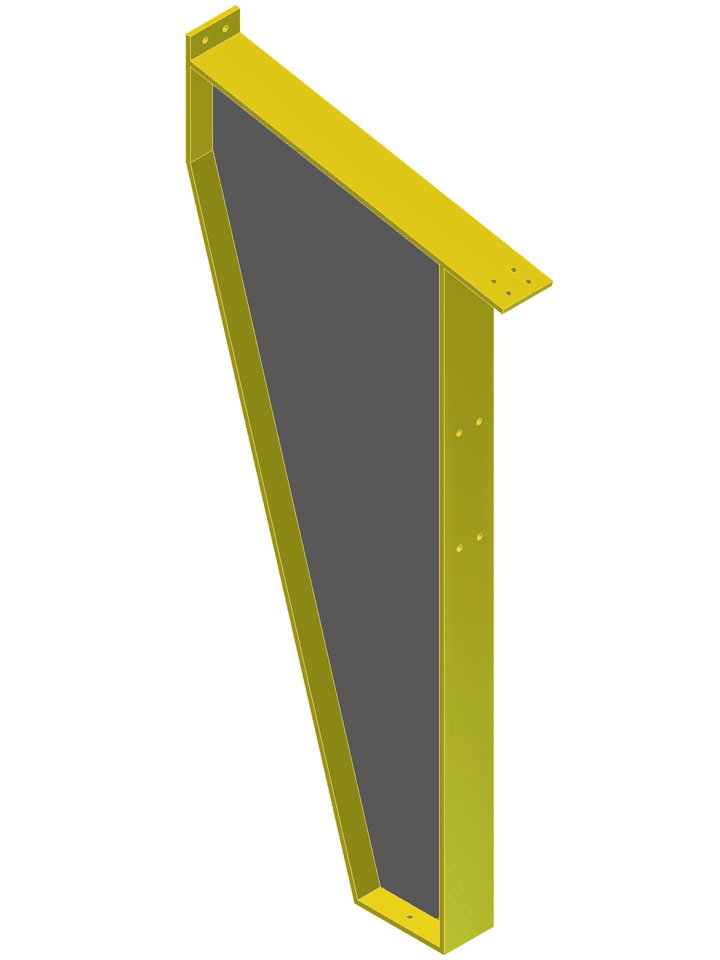

- Single and Dual Punch options

- Clip location marking option

- Alpha-Numeric Part Marking option

- Single-Cut shear for cut-to-length

- In-feed loading options

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Material Positioning Speed | 0 to 180 ft/min |

| Accuracy | +/- 1/32" |

| Maximum Material Size | 12" (304.8mm) x 1" (25.4mm) |

| Minimum Material Size | 3" (76.2mm) x 1/4" (6.35mm) |

| Standard 250 Ton Double-Punch | Max Hole: 1-5/16" (33.3mm) through 1" (25.4mm) @ 70 ksi shear strength |

| Standard 215 Ton Single-Punch | Max Hole: 1-11/16" through 1" @ 80 ksi shear strength |

| Kerf | 0 |

The Flange Line control system has an easy to use interface. As the machine runs, the status of each part or operation changes in real time. A part list dialog can be displayed to show which parts have been completed or which operations are remaining. The Windows controller can be easily networked for downloading of parts from the office or by most drafting and design programs. Parts can also be easily programmed at the machine, even while parts are being run.