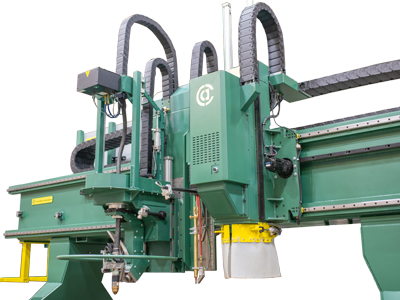

The GPF-10X and GPF-8X is Controlled Automation’s best selling large capacity combination plasma and drilling system produced for plate processing. The GPF offers drilling capabilities and high definition XPR plasma straight and contour bevel-cut parts all on one system. With a core machine design of strength and stability, fast and responsive controls, along with the advantage of oxy-fuel cutting beyond the maximum thickness of plasma, precision parts are created quickly and easily. This machine can be customized to fit your exact requirements, with multiple drilling operations and a fully automatic tool-changer. Features such as variable travel lengths, widths, service track positions and material handling allow for flexibility fitting in your size work environment.

This robust gantry system is ideal for large components and plate that requires the upmost accuracy. By working over the plate and not moving the workspace back and forth, as on a pull-through design, we are able to keep the highest of tolerances and process the entirety of the stock material.

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Machine Specifications | |

| Spindle | CAT40 / 20HP |

| Maximum Spindle Speed | 2,100 RPM Variable |

| Drilling Capacity | Up to 6" thickness |

| Drilling Capabilities | 2-1/4" max diameter (57mm) (without milling)

Helical Interpolation for any size diameter hole Fully Automatic Tool-Changer Counter Boring Counter Sinking Tapping Surface Milling Rotary Scribing |

| Coolant System | Thru-Spindle Coolant (Flood optional) |

| Maximum Width | 8' to 10’ (2.43m - 3m) |

| Maximum Travel Length | Up to 153’ (46m) |

| Maximum material thickness | 6” piercing start (152mm) |

| Cutting Surface | Various Configurations of Down-Draft or Water-Table (preffered) |

Both the motion of the gantry and length axis is driven along a linear rail and block system by use of AC Servo motors (one on each side of the gantry for movement in the Y axis and one for tool movement in X) coupled to low backlash planetary gear reducers. We use the highest quality gear reducers on the market to reduce backlash when changing directions and to ensure a very long dependable lifespan. The planetary system produces extreme power and performance in a very small package. Helical rack and pinions are used to reduce cogging and vibrations that are typical when using straight rack and pinions. When combined in a system, AC servo motors and helical rack and pinion provide smooth motion and high acceleration rates, producing optimum plasma and oxy-fuel accuracy and cut quality.