The most rugged 8' (2.5m) wide Combination Drilling & Thermal Cutting Plate Machine

-

Precision Drilling & Burning of longer and thicker parts than any pull-through designed machine

The BTD-8X combines Controlled Automation's shape cutting and high speed drilling technologies to produce top quality thermally cut contoured parts with drilled and/or thermally cut holes. With a core machine design of strength and stability, fast and responsive controls, and the advantages of high definition plasma and high speed carbide drilling, accurate high quality parts are created quickly and easily with the BTD-8X.

-

High Definition Plasma / Drilling / Oxy-fuel cutting

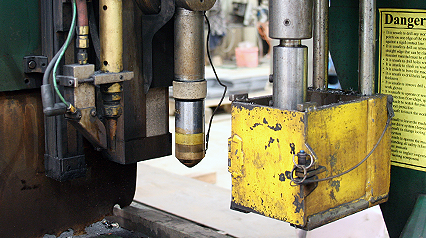

The BTD-8X utilizes three key tools for plate production: High definition plasma, high-speed drilling, and an oxy-fuel torch station. Our plasma is supplied with automatic gas & True Hole Process for the best cut quality available on any combination plate machine. The Controlled Automation software communicates with the plasma to adjust the gas flows, pressures, and amperages in real time. With this capability, the system can create layout marks, identification, and reference information as well. The Oxy-Fuel system also automatically sets the gas pressures depending on the plate thickness and torch tip being used. Drilling is done with a precision ball-screw feed for high speed carbide drilling up to 1-9/16" (40mm) diameter holes with tool life monitoring.

-

Bridge Design

The machine bridge is a tubular steel section that has been stress relieved after welding, then machined down its length to provide a flat, straight seat for the guide rails. This provides superior accuracy for all tools. The tubular steel section is filled with a material designed to lower its resonant frequency which reduces vibration while high speed carbide drilling. The bridge is driven along the rail system length by use of dual AC servo motors (one on each side) coupled to low backlash planetary gear reducers. Helical rack and pinions are used to reduce cogging and vibration as normally witnessed when using straight rack and pinions.

-

SICAM Advanced Plate Nesting

Controlled Automation offers the cutting edge (no pun intended) in advanced shape nesting software and beyond. Our SICAM software is used throughout all Controlled Automation machinery for easy navigation between machines for the operator. We also allow seamless integration with a variety of communication tools unavailable on any other cutting machine in the world. Whether you need to tie into 3D drafting models such as Design Data SDS-2 and Tekla detailing software or communicate with inventory management software such as FabTrol and FabSuite, SICAM is on board as the standard nesting program to handle the cutting edge of production.

-

Guide rails and wheels

The bridge is supported by four pivoting wheel assemblies. Each pivoting wheel assembly houses two hardened support wheels for a total of eight wheel supports. By supporting the gantry with eight wheels in contact with the rail surface instead of four, the lives of the wheels, support rail, and wheel bearings are doubled. The wheel assemblies on the guide side are “V” groove wheels which guide the machine on the same path as the guide side rail rolling surface. The wheel assemblies on the opposite side of the gantry are flat across the wheel face. This allows for thermal expansion and compliance between the machine and the rail system interfaced. The rail rolling surfaces are hardened and ground round shafting running the length of each rail providing a very durable long lasting support for the bridge.

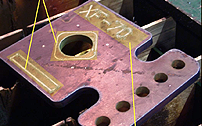

High Definition CuttingPrecision parts are produced using Hypertherm's True Hole process as standard on our HPRxd series machines for AISC approved bolted hole connections for the structural fabricators.

High Speed Carbide DrillingThe drill tool feeding system uses a precise closed loop AC servo ball screw assembly. Velocity, torque, and position are all controlled at a 1 KHz sample rate. Through spindle coolant is also used at the front of the cutting edge of the drill bit for a minimal use of coolant and less mess.

Cutting SurfacesBoth water tables or downdraft tables are available on the BTD-8X. Water tables being the most economical by its use of very inexpensive and replaceable wood slats that protect carbide tipped drill bits.

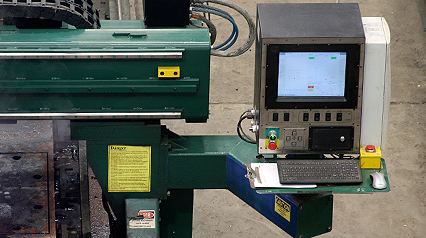

Control SimplicityThe operation of the machine is designed to be user friendly. The BTD-8X operating software provides a variety of ways to program or import parts or a nested plate of multiple parts. Parts can be created or imported from multiple file formats (CNC, DXF, DSTV, etc..)

Part MarkingPart marking is accomplished by using a lower amperage setting in a plasma system. When automatic gas control is used, the Controlled Automation software communicates with the plasma to adjust the gas flows, gas pressures, and the amperage setting on the plasma without the need to change consumables.

Down-Draft or Water Cutting SurfacesZoned down-draft systems or water tables are available on all model BTD-8X machines. Dross pick-out trays are included in each design for easy clean out.

Superior Service & SupportAs the most trusted name in service and support - Controlled Automation leads the industry for inexpensive parts and the highest quality service that speaks more from our loyal customers than any marketing. If you own a Controlled Automation machine, you are our customer and we will support you for life.

Specifications

| Effective Cutting Length | 10' to 124' (3m to 37.8m) | |||

| Effective Cutting Width | 8' (2.5m) | |||

| Drive Configuration | Rack and Pinion, with AC digital servo amplifiers | |||

| Machine Speeds | Rapid Traverse 845 IPM | |||

| Positioning Accuracy | ±.007in. | |||

| Body Construction | Low Resonance Gantry | |||

| Dual Side Drive | All Models | |||

| TOOLS | Specs | |||

| 1 Oxy-Fuel torch (max) | Automatic gas control | |||

| 1 Plasma station (max) | Automatic gas control | |||

| 1 Drill station (max) | 10HP / #4 morse taper | |||