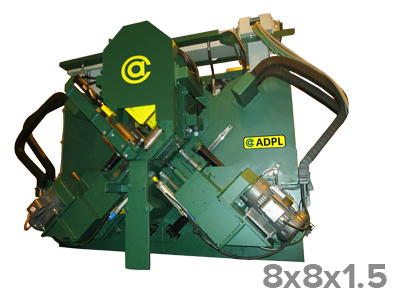

The ADPL is our largest capacity angle and flat bar system. It is capable of processing both angle and flat bar up to 1-1/2" material thickness; beyond any punching and shearing design on the market. The ADPL accomplishes this capacity through its use of high-speed carbide drilling and combination high-speed saw for its cut-to-length.

Utilizing our drilling technology from Controlled Automation structural drilling lines, the ADPL performs with patented break-through technology and high-speed ball-screw feed for extreme accruacy and high-speed material production.

Drilling and the use of a high-speed saw, it allows for both an econmical and ultra-fast solution ideal for bridge fabrication, seismic and other work that does not allow for a punched and/or shear cut process.

- Highly accurate Length Measuring X-Probe

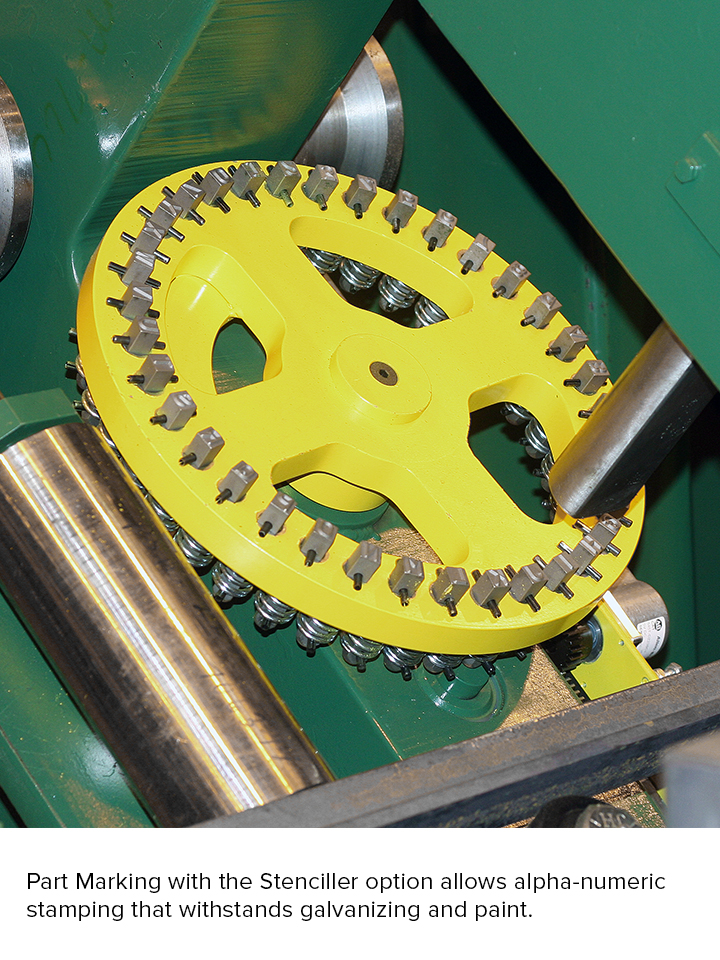

- Part Marking that withstands galvanizing and paint available

- Loading and unloading features available

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Material Positioning Speed | 0 to 250 ft/min. (0 to 76.2m/min.) |

| Accuracy | ± 1/32” ( ± 1mm) Electronically |

| Maximum Hole Size | 1-7/8” (47.625mm) |

| Saw speed | 20-100 m/min (66-328 fpm) |

| Saw Blade size | 5300L x 41W x 1.3T mm (208.7" x 1.6" x 0.050") |

| Maximum Length of Stock Material | 40’ (12.2m) Standard / other lengths optional |

| Minimum Length of Stock Material | 6’ (1.8m) |

| Maximum Angle Size | 12" x 12" x 1-1/2" (304mm x 304mm x 38mm) |

| Minimum Angle Size | 2” x 2” x 1/4” (50.8mm x 50.8mm x 6.35mm) |

| Maximum Flat Bar Size | 12” x 1-1/2” (304mm x 38mm) |

| Minimum Flat Bar Size | 3/8” x 4” (9.53mm x 101.6mm) |

The ADPL is our largest capacity angle and flat bar system. It is capable of processing both angle and flat bar up to 1-1/2" material thickness; beyond any punching and shearing design on the market. The ADPL accomplishes this capacity through its use of high-speed carbide drilling and combination high-speed saw for its cut-to-length.