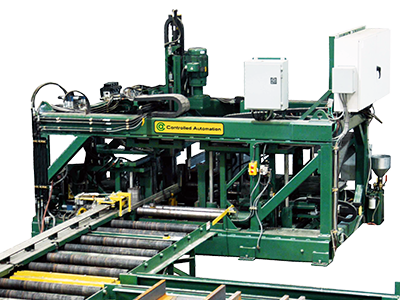

The Bridge Girder Drill is a portable gantry style drilling machine, designed to provide fast and accurate multi-ply drilling of structural girders without the use of pre-drilled templates. This machine is offered in a vertical spindle drilling model or a horizontal spindle drilling model. The Girder Drill can be mounted to optional leg and wheel assemblies making it easy to reposition along any length after each drilling operation is completed. This machine has a 20hp spindle motor and #4 morse taper to provide fast drilling whether using carbide, spade or twist bit tooling. The Girder Drill comes standard with a laser dot position verification feature, which allows for the part program to be skewed to match the actual material orientation. This eliminates having to square the machine with the material which greatly increases processing times.

- Drilling window based on customers specifications

- Hole patterns can be saved and mirrored

- Windows CNC

- High-Speed Carbide Drilling

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Horizontal Model's Typical Operating Window | X-Axis 12' ft Y-Axis 5' ft |

| Vertical Model's Typical Operating Window | X-Axis 14' ft Y-Axis 8' ft |

| Typical Weight | 7,800 lbs |

| Drill Spindle | 20HP |

| Drill Speed | 300-1200 RPM variable speed |

| Minimum hole diameter | 3/16" (76.2mm) |

| Maximum hole diameter | 2-1/2" (50.8mm) |

| Minimum drillable thickness | 1/4" (25.4mm) |

| Maximum drillable thickness | 10" (254mm) |

The horizontal design has a bridge that is a tubular steel section that has been stress relieved after welding, then machined down its length to provide a flat, straight seat for the guide rails. Angular support brackets are mounted all around the perimeter of the base frame system and are gusset reinforced with 3⁄4” through holes to allow work holding and lifting fixtures to be attached and/or the machine to be mounted (if applicable). The machine is mounted upon I-Beam support legs orienting the drill spindle in the horizontal plane for ease of setup while drilling flanges of plate girder in the lay down position. Specialized work support and clamping fixtures need to be determined by customer and are quoted separately.