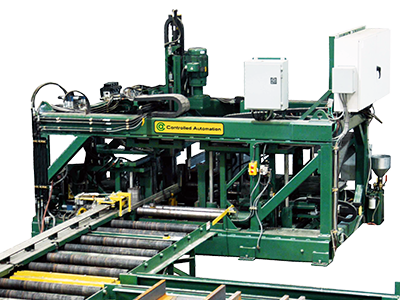

Multiple Hole Punching System

This is a Beam punch system dedicated to manufactures looking to process multiple hole patterns all at once. For processing batches of the same beam, this is the fastest way to do it. It is important to remember the economics of punching verses drilling. Punching a hole can be up to 4 times faster, and at a fraction of the tooling cost. With punching multiple holes at once, that time is even faster.

Punching also offers the ability to have shaped holes and slots. Our 175 ton (standard) punch frames have the strength to handle most of the manufacturers needs for materials up to 1" in thickness.

The BFC-Custom also comes with the same material handling options as our drilling and coping systems. This allows easy integration to an existing or new line. Options such as dual-gag, for varying hole sizes.

One of our latest features is the optional 'Slug Sucker' for the automatic removal of slug holes from the beam on our top flanges of the double-punch frames.

- Double-punching on each flange

- Tandem straight and miter saw options

- Material processing up to 1" inch thick

- Material handling options for various weights and capacities

- Stamp-style part marking option that withstands

galvanizing and paint - Web punch unit also available

USA 🇺🇸 manufactured

From the design to the steel itself, we produce USA manufactured solutions.

Service

Our in-house service technicians offer minimal downtime and free phone support for the life of your machine.

Local Parts

We offer customers with off-the-shelf and readily available parts for the best uptime possilbe and less costs.

Windows control

The Windows control allows for simple service and operation in a familiar and easy to work in environment.

| Material Capacity | |

| Maximum Material lbs/ft | 300 lbs/ft (41.5kg/m) |

| Maximum Material Thickness | 1" (25.4 mm) |

| Maximum Material Width | 18" (457.2mm) |

| Maximum Slug Hole Size | 1-5/8" (40mm) round |

| Maximum Slot Size | 3" (76.2mm) round |

| Flange Punch Capacity | 175 tons (standard) |

| Positioning Speed | 0 to 183ft/min (56m/min) |

| Material Types | W, HP, C, MC |

The BFC-Custom is one of the fastest machines to process multiple holes at once in structural steel shapes. With the advantage of using inexpensive punch and die tooling, it saves on costs per hole to produce parts. This system is one of our best built machines for decades of hard work, high-speed production and profit.